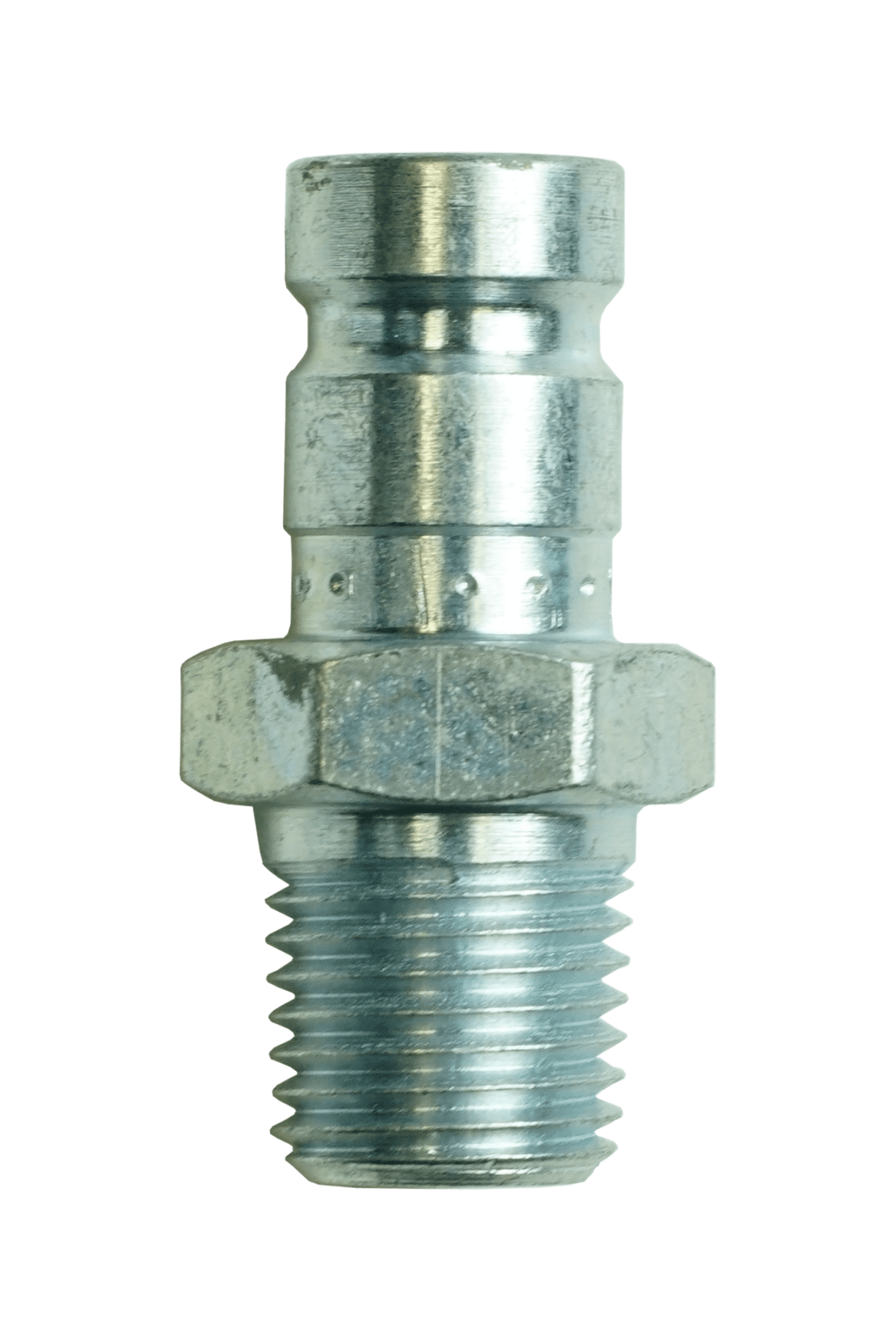

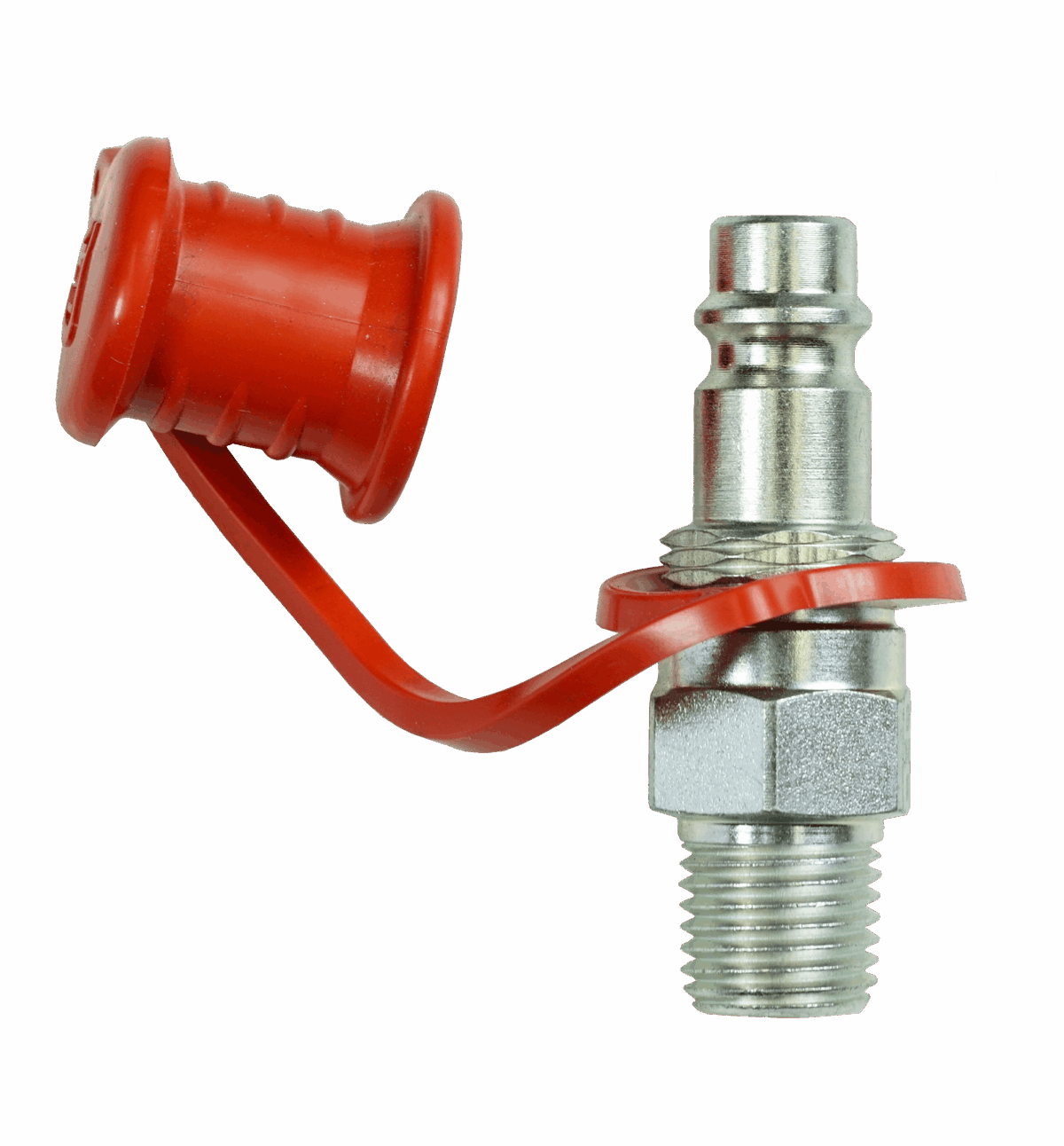

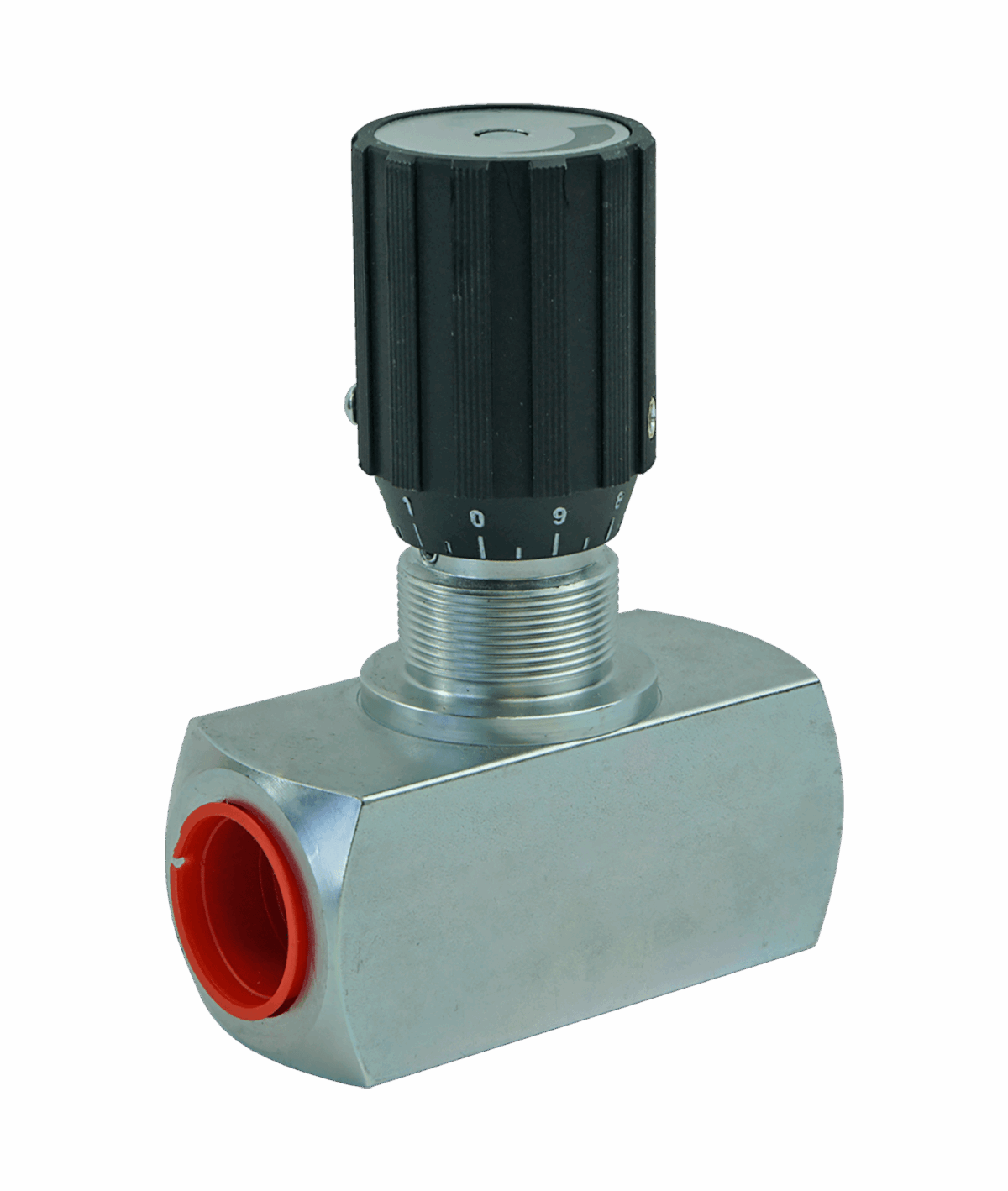

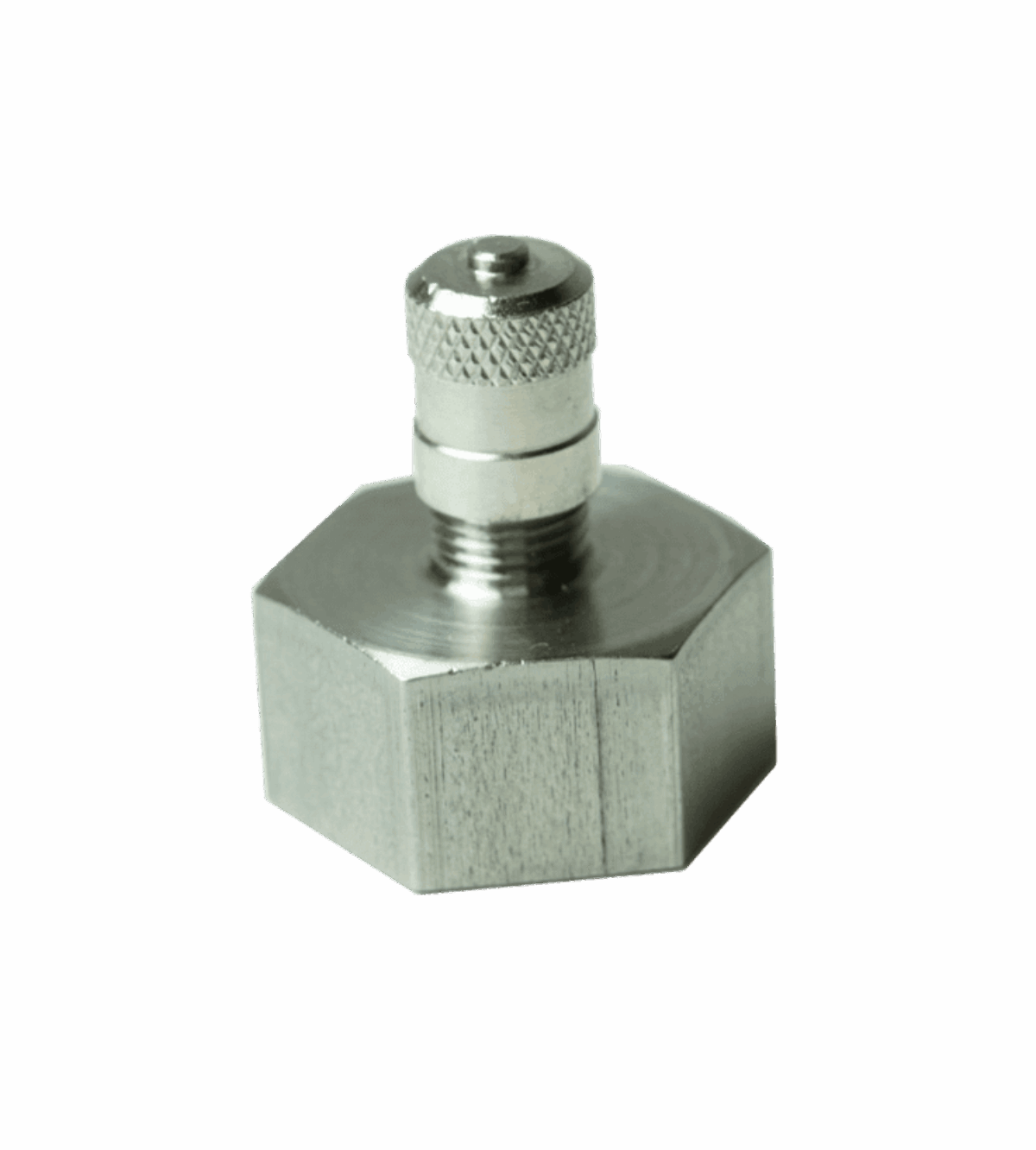

The MicroLeak test kit allows safe and accurate field-testing of hydraulic components, particularly pressure control valves, check valves, directional control valves, and circuit modules, without ever having to exhaust pressurized oil into the atmosphere.

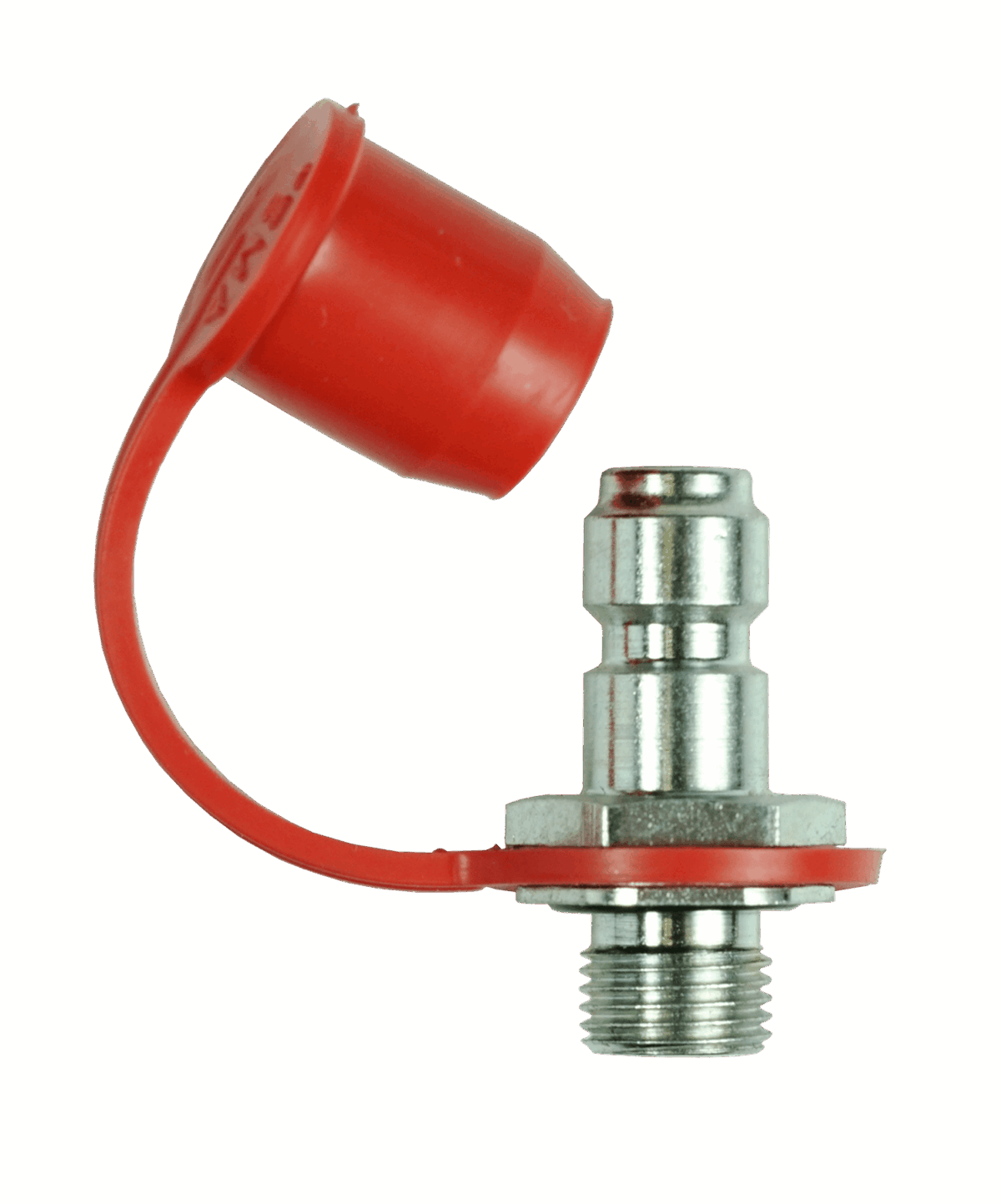

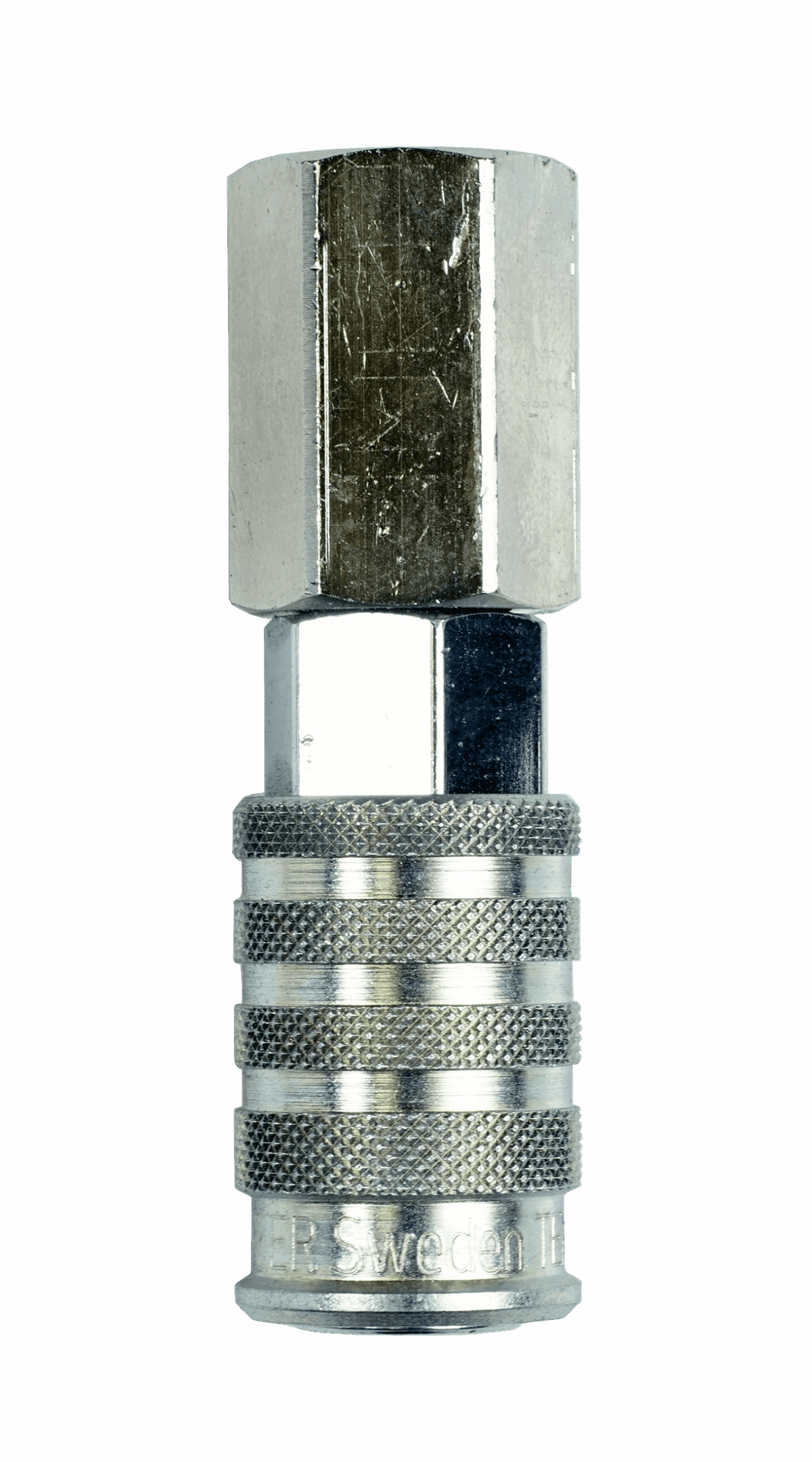

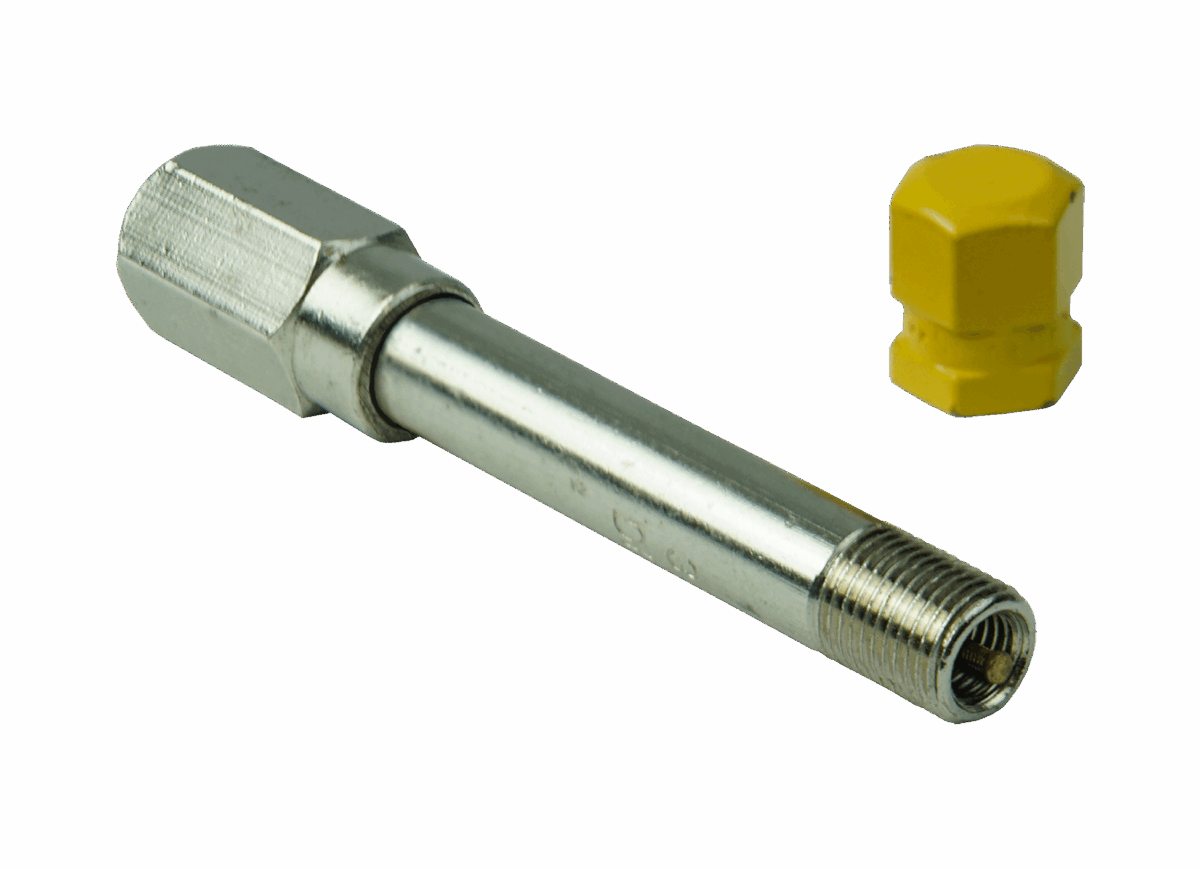

Packaged in a rugged carry-case, you will find all the adaptors you need to MicroLeak test hydraulic components equipped with:

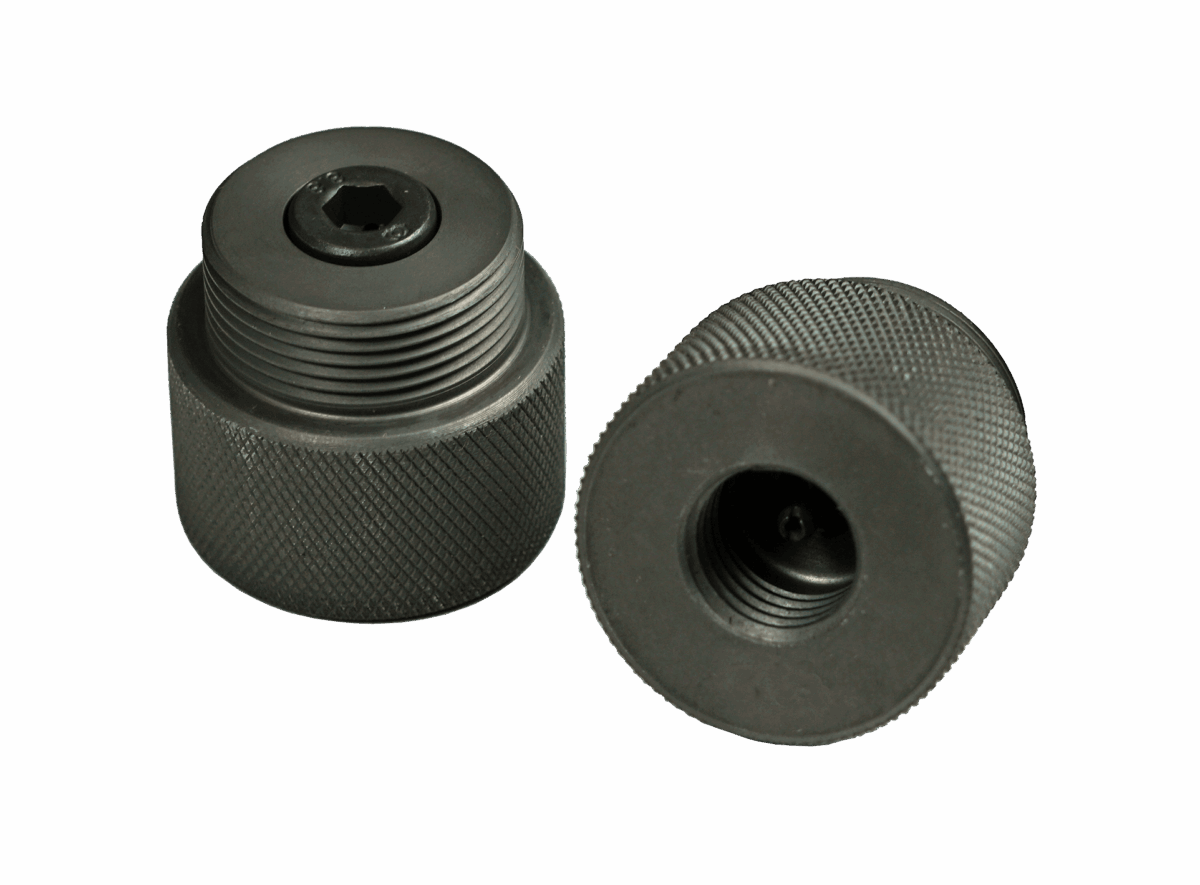

Male pipe (NPT) plugs – 1/4″, 3/8″, 1/2″, 3/4″, 1″, 1-1/4″ Oring Boss (SAE) straight thread connectors – #4, #6, #8, #10, #12, #16, #20, #24 JIC 37º female connectors – #4, #6, #8, #10, #12, #16, #20, #24 ORFS female connectors. – #4, #6, #8, #10, #12, #16, #20, #24 Split flange (code 61) connectors. Split flange (code 62) connectors.

The HC-TK2000 test kit includes: