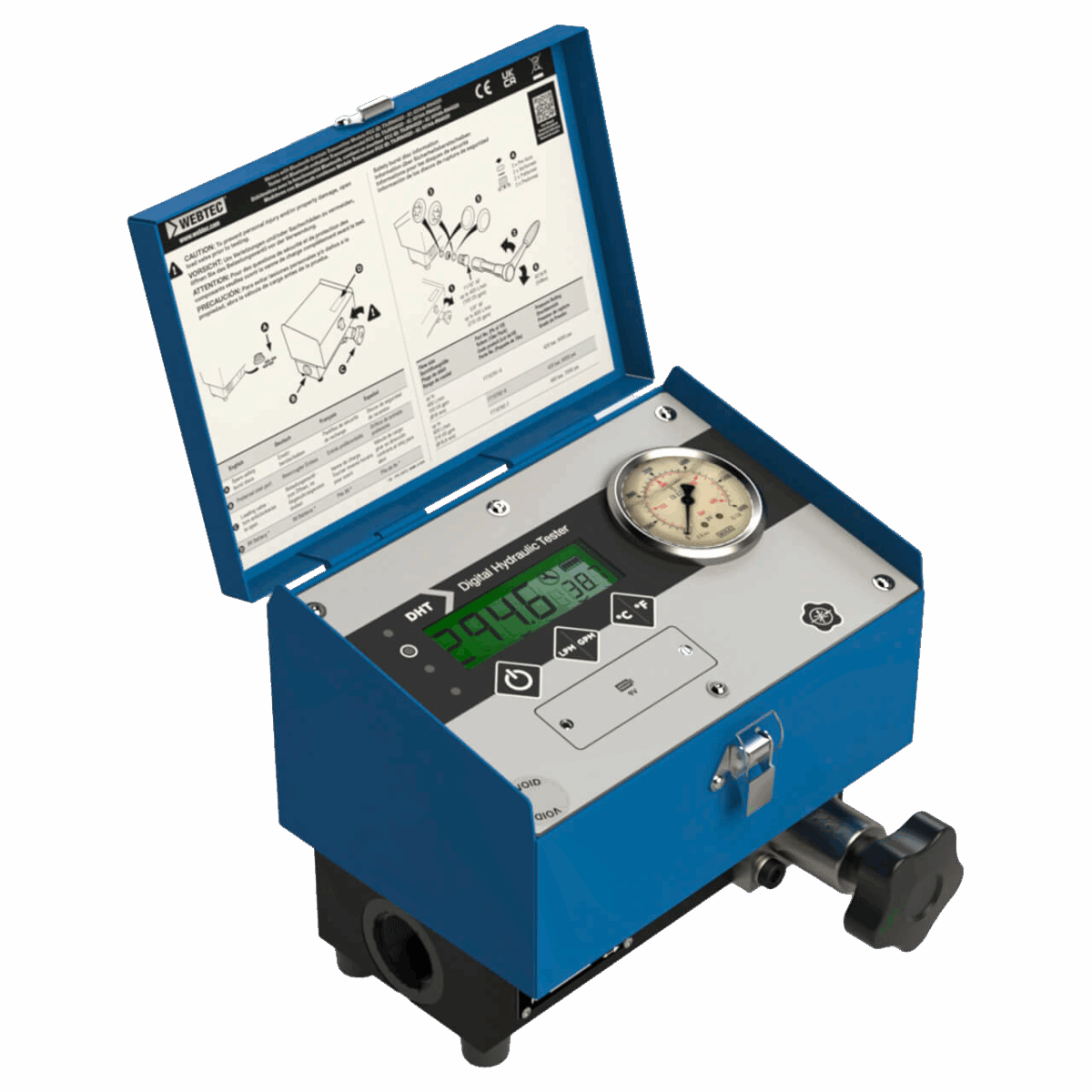

The Service Master CONNECT (HPM7000) is a powerful diagnostic measuring device for mobile, stationary hydraulic applications, e.g. in the area of service, commissioning, and development. It safely and accurately records values such as pressure, temperature, flow, and frequency.

Thanks to the robust IP65 design, it offers comprehensive protection against moisture and dirt and is resistant to impacts. Therefore, the device is very suitable for use in harsh environments.

The 7″ large, illuminated, non-reflective display enables smooth, intuitive operation. The clearly structured user interface which enables fast and secure measurement setting configuration makes the device easy to use. The modular measuring device hardware and software enables customized setup according to individual measuring and analysis needs (See below). It measures and displays up to 100 channels and is therefore also suitable for very complex diagnostic tasks.

The base model enables you to simultaneously measure up to 48 CAN channels. Alternatively, up to 5 External CANOpen channels can be connected. Two frequency inputs…